The Rising Star in Industrial Applications: Sodium Silicate sodium metasilicate 9h2o

- by admin

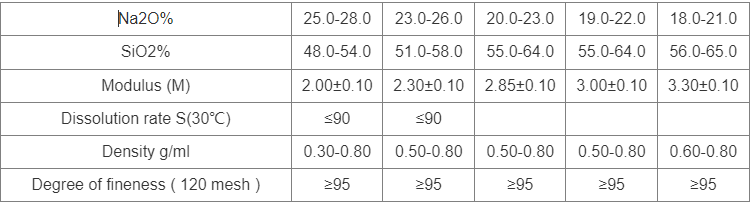

Technical Parameters of Powdered Instant Sodium Silicate (CAS 1344-09-8)

(Technical Parameters of Powdered Instant Sodium Silicate (CAS 1344-09-8))

Keep in mind: We can additionally tailor sodium silicate powder with moduli of 2.45, 2.5, and 3.4 according to your needs.

Our Variety Of Salt Silicate Moduli

We provide powdered instant sodium silicate with moduli ranging from 2.0 to 3.3. In addition, we can personalize sodium silicate powder with moduli of 2.45, 2.5, and 3.4 to satisfy your details demands.

Salt silicate, likewise referred to as water glass, has amassed considerable interest owing to its large range of applications throughout diverse markets.

Composed of sodium oxide (Na2O) and silicon dioxide (SiO2), this compound can be discovered in kinds ranging from strong granules to aqueous services, depending upon the proportion of these two components. Its unique features, consisting of strong glue residential properties, durable thermal security, and acid resistance, render it a vital material in industries such as building and construction, vehicle manufacturing, and various other production markets.

Versatile Uses Throughout Industries

In the building and construction industry, salt silicate serves as a key component in concrete sealants and fireproofing agents, enhancing sturdiness and safety and security. It is also made use of in the manufacturing of adhesives and binders for making abrasive materials and refractory products. In the automobile industry, salt silicate is crucial for making mold and mildews for casting engine components due to the fact that it can sustain heats without wear and tear. Furthermore, its usage in water treatment processes for softening tough water highlights its flexibility in resolving environmental issues.

Environmental and Safety And Security Considerations

Regardless of its extensive use, the handling of salt silicate calls for mindful factor to consider of environmental and security guidelines. While it is generally thought about risk-free, extended exposure can create skin irritability, and its dust can irritate the respiratory system. Adherence to proper disposal techniques is critical to avoid contamination of water bodies and the succeeding injury to aquatic microorganisms. Suppliers and customers are increasingly embracing lasting practices to alleviate the ecological influence of sodium silicate production and usage.

( sodium silicate)

Conclusion

The overview for sodium silicate is intense as scientists continue to uncover new uses and boost existing applications. Given the continuous technical developments and the enhanced emphasis on sustainability, this multi-faceted compound is readied to play a significantly main function in driving commercial developments. As markets advance, so as well will certainly the methods which sodium silicate contributes to satisfying the difficulties of the 21st century.

Premium Sodium Silicate distributor

TRUNNANO is a supplier of Sodium Silicate Materials with over 12 years of experience in nano-building energy conservation and nanotechnology development. It accepts payment via Credit Card, T/T, West Union and Paypal. Trunnano will ship the goods to customers overseas through FedEx, DHL, by air, or by sea. If you want to know more about sodium metasilicate 9h2o, please feel free to contact us and send an inquiry(sales5@nanotrun.com).

All articles and pictures are from the Internet. If there are any copyright issues, please contact us in time to delete.

Inquiry us

Technical Parameters of Powdered Instant Sodium Silicate (CAS 1344-09-8) (Technical Parameters of Powdered Instant Sodium Silicate (CAS 1344-09-8)) Keep in mind: We can additionally tailor sodium silicate powder with moduli of 2.45, 2.5, and 3.4 according to your needs. Our Variety Of Salt Silicate Moduli We provide powdered instant sodium silicate with moduli ranging from…

- Analysis of the various types and differences of concrete reinforcing fibers properties of fiber-reinforced structural and non-structural ultra lightweight aggregate concrete

- Unlocking New Frontiers: The Potential of Lithium Silicate Aqueous Solution ca fe

- Unlocking New Frontiers: The Potential of Lithium Silicate Aqueous Solution ca fe

- The Invisible Workhorse: Uncovering the Power of Surfactants alpha olefin sulfonate

- Concrete Foaming agent vs. Defoamers: How to Choose the Right Admixture for Your Project? hydroxy propyl methyl